DIEMETALLMACHER

individuell | hochwertig | beständig

Unsere Philosophie

Metall ist unsere Leidenschaft. Und daher widmen wir dem Werkstoff unsere ganze Aufmerksamkeit. Seit vielen Jahren beschäftigen wir uns damit, wie Metalloberflächen mit handwerklichen Mitteln verändert und gestaltet werden können. Durch die Verbindung modernster Fertigungsverfahren mit traditioneller Metallhandwerkskunst erschaffen wir hochwertige und individuelle Produkte, die Sie für Jahrzehnte begleiten werden.

Unser Qualitätsanspruch

Unsere Produkte sind stabil und hochwertig, aber zugleich filigran und leicht. Jedes unserer Produkte wird nach den höchsten Qualitätsstandards mit dem Laser auf den Zehntel Millimeter genau ausgeschnitten und dann in Handarbeit veredelt. Je nach gewünschter Oberfläche sind dafür bis zu zehn einzelne Bearbeitungsschritte notwendig. Erst wenn uns selbst das Bild der Oberfläche begeistert, verlassen die Produkte unsere Manufaktur.

Die verwendeten Materialien

Unser besonderes Augenmerk liegt auf der Eignung und Qualität der verwendeten Materialien. Wir verlassen uns ausschließlich auf Stahlsorten, die hochwertig und für den jeweiligen Einsatzzweck am Besten geeignet sind. Für unsere Edelrost-Produkte verwenden wir in erster Linie Corten-Stahl. Dabei beeinflussen wir den Oxidationsprozess ganz gezielt und schaffen so ganz individuelle Rostlandschaften. Bei unseren Produkten aus rostfreiem Edelstahl treten Werkstoff und Oberfläche in den Hintergrund, dafür wird die Geometrie betont und Sie können sich ganz auf die Wirkung konzentrieren. Unsere Edelstahlprodukte eignen sich besonders, wenn Sie Ihrem Zuhause ein modernes Element hinzufügen wollen.

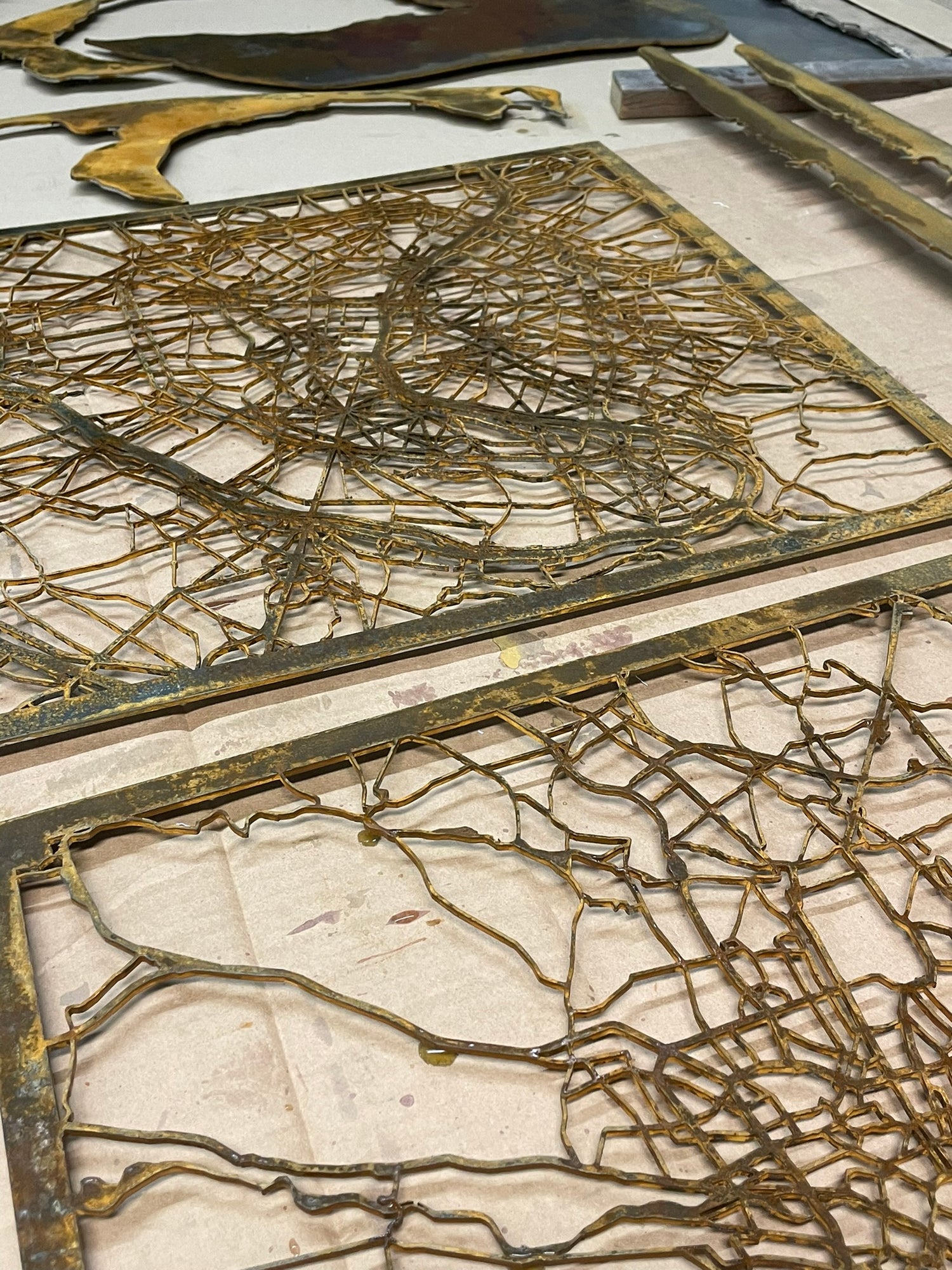

Geographie als Inspiration

Die Form vieler unserer Produkte entstammt geografischen Mustern. Die zeitlose Ästhetik der Umrisse von Kontinenten, Ländern, Inseln oder das filigrane Netz von Städten und Dörfern begeistert uns immer wieder aufs Neue. Es sind unendlich viele Formen, Ausschnitte und Umrisse, die Sie auf den Landkarten dieser Welt entdecken können. Wir verewigen sie in unseren Produkten, so dass Sie sich jeden Tag daran erfreuen können.

Unser Fertigungsprozess

Unser Anspruch ist es, hochwertige und individuelle Produkte zu schaffen, die unseren Kunden über viele Jahrzehnte Freude bereiten. Daher sind all unsere Fertigungsprozesse konsequent auf Langlebigkeit und Qualität ausgerichtet.

Erschaffung des digitalen Musters

An erster Stelle steht die Auswahl der geographischen Form, die wir in Metall bannen wollen. Wenn wir uns (ggf. mit Ihrer Hilfe) für ein Motiv entschieden haben, erstellen wir eine digitale Version des Musters. Dabei steht die ästhetische Wirkung im Vordergrund – nicht alle Details können abgebildet werden, nicht alle Elemente einer Landkarte können überlagert werden. Zugleich geben die Modelle aber auch feinste Details wieder.

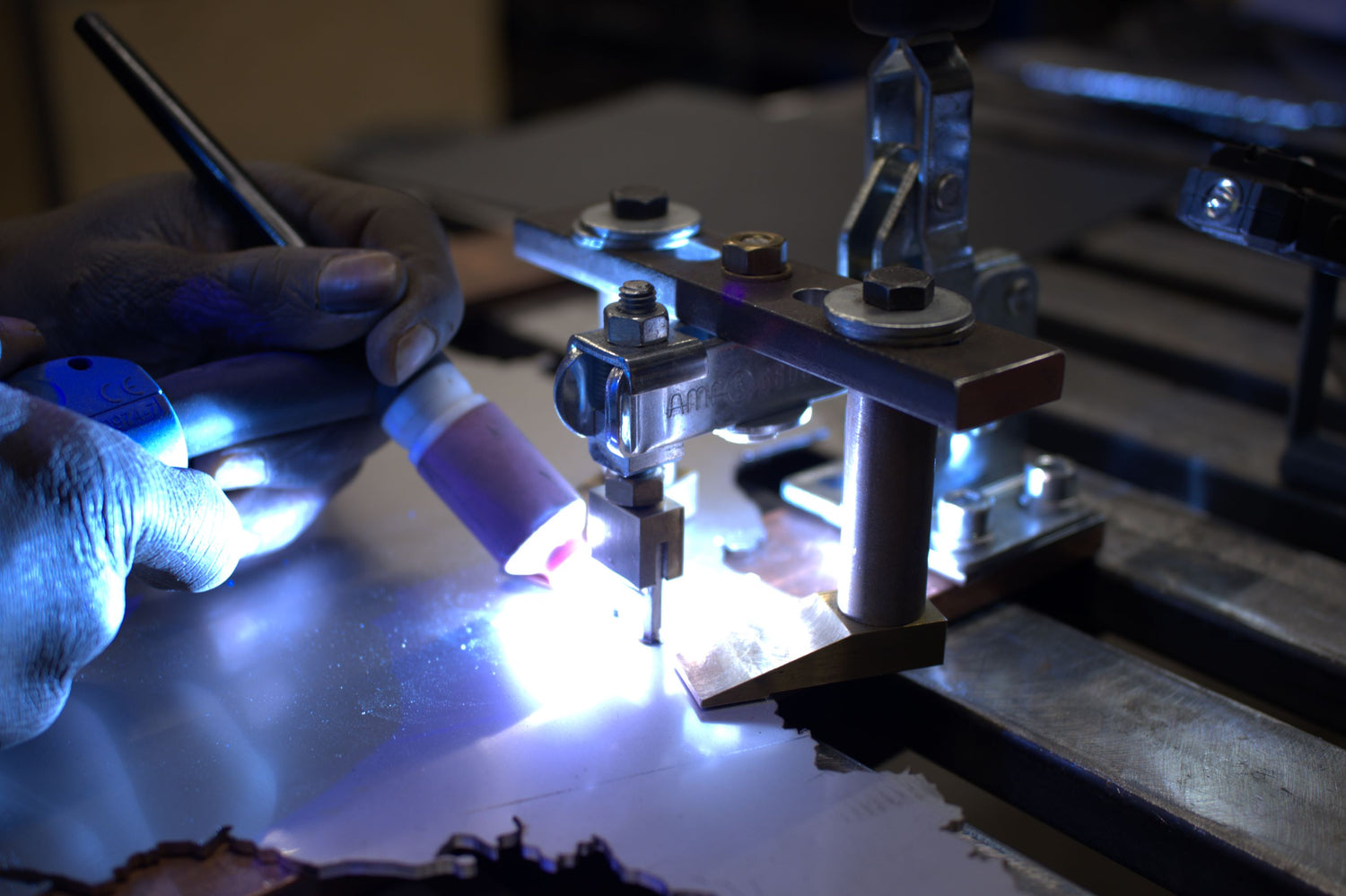

Zuschnitt mit dem Laser

Alle unsere Produkte bestehen aus hochwertigem Stahlblech mit mindestens 3mm Materialstärke. Das unterstreicht die Hochwertigkeit der Produkte. Wir verwenden unterschiedliche Legierungen, je nach der angestrebten Verwendung und optischen Erscheinung. Basierend auf dem digitalen Muster wird das Muster mit dem Laser auf den Zehntelmillimeter genau aus dem gewählten Material ausgeschnitten. Um den filigranen Charakter zu erhalten und auch kleinste Details abzubilden, gehen wir hier bis an die Grenzen des technisch Möglichen.

Die Veredelung der Oberflächen

Im nächsten Schritt werden die Oberflächen der Produkte veredelt. Dabei setzen wir auf handwerkliche Bearbeitung durch Schleifen und Polieren. Auch hier steht die Ästhetik im Vordergrund, zugleich sorgen wir aber auch für Funktionalität und Sicherheit der Bauteile – zum Beispiel indem wir scharfe Kanten eliminieren. Die handwerkliche Bearbeitung sorgt für höchste Qualitätsstandards, aber auch dafür, dass jedes Produkt in feinen Nuancen ein Unikat ist.

Anbringen der Halterung

Bei unseren Wanddekorationen werden anschließend die von Ihnen gewählten Befestigungsvorrichtung angebracht. Alle unsere Befestigungsarten sorgen dafür, dass ein besonderer Tiefeneffekt entsteht.

Behandlung der Edelrostprodukte

Unsere Edelrostprodukte unterziehen wir abschließend einer genau austarierten Oberflächenbehandlung in mehreren Schritten. Dabei aktivieren wir die Korrosion der Stähle genau in dem Maße, um den gewünschten Rost-Effekt zu erhalten. Der Effekt ist immer einmalig. Abschließend behandeln wir die Produkte je nach Verwendung mit einer schützenden Schicht aus Lack, um die eingestellte Oberfläche zu konservieren.